Ford updated its Customer Specific Requirements, discussed family, foundation, and part FMEAs, and required Ford suppliers to adopt an FMEA software package by July 1, 2022. Ford requires Reverse FMEAs (RFMEAs) to be implemented into Process FMEAs (PFMEAs).

All Foundation PFMEAs for all manufacturing processes (current and forward model) and subsequent updates to all FMEAs must be available in the FMEA software starting December 31, 2022.

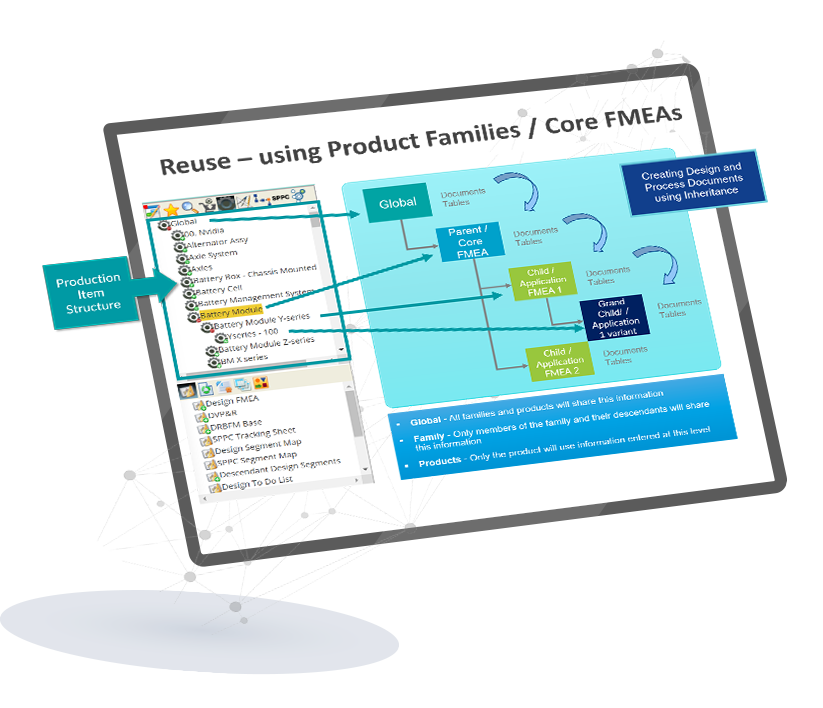

Foundation FMEAs present the generic content of FMEA for product families or manufacturing processes and can be used as a starting point for developing specific FMEAs.

Foundation FMEAs present experience and knowledge from the past. They are a collection point to collect and present knowledge during the service life of a product. Earlier problems should not be repeated (lessons learned aim to learn from failures rather than repeating them). However, it also makes it possible to create specific FMEAs with less workload.

Foundation FMEAs with software often reduce the cost of creating Design and Process documents. When used in concert with family FMEAs can reduce the effort and cost by as much as 80%. It is generally referred to as Design and Process reuse. Organizations are required to have foundation FMEAs.

The foundation FMEAs are not a replacement for Part FMEAs. They provide a base and generic content, which could be modified when it comes to the part family level or specific part number. There is a hierarchy of structure from the foundation to part families and specific part members.

Foundation FMEAs play a critical role in preventing recurrence by capturing knowledge from problem-solving and ensuring errors are not repeated in future launches. Knowledge gained from problem-solving processes (8D, 6-Sigma, etc.) shall be documented in both the part and the foundation FMEAs.

The FMEA is a prevention tool, the issues, and problem, i.e., detection is captured by the 8-D (both external and internal issues). The FMEA captures lessons learned as a part of the D7 Step of the 8D.

The organization may write FMEAs for families of parts, where typically the only difference in the parts is dimensional, not form, application, or function. The organization should obtain Ford STA review and concurrence before the use of the family process FMEAS. The organization is also required to obtain Ford PD review and concurrence before the use of family design FMEAs.

Organizations are required to have a process in place that ensures all new launches complete an RFMEA event once the equipment is installed and running. This process should be first completed at the equipment manufacturer and then after final installation, on the organization's plant floor.

The reverse FMEA involves design and process engineers working with operators and attempting to make bad parts, beat the error proofing and find new failure modes, causes, and develop controls. The goal is to discover opportunities and implement improvements in the FMEA that were not previously discovered. Evidence of Reverse FMEA events must be available starting July 1, 2022, for forward model programs that have not yet completed Job 1.

A team, using the PFMEA information, walks through the process, testing it to make sure that they have all potential errors identified by the PFMEA for each work station, if a discrepancy occurs, how long through the system does it take to be discovered, and Updating the PFMEA based on lesson learned and changes made.

Speakers:

Antony John

Watch RecordingSpeakers:

Chad Kymal, Antony John, Gregory Gruska, Nikhil Unnikrishnan

Watch RecordingWith One Of The Writers Of The AIAG-VDA FMEA Handbook

Speakers:

Mary Rowzee

Watch RecordingSpeakers:

Dave Watkins

Watch Recording

In EwQIMS, there is the foundation FMEA at the global level, and there is the feature of inheritance in Omnex, making it possible for information added at the global level to inherit to Parent 1 to Parent 2 and then into any children or grandchildren under them. Any required changes can also be done for any Part family alone.

If certain information which exists at the child FMEA is required to be promoted to the global level, this can also be done so that all the other product families can have access to this information.

The presence of a problem-solving module as part of the EwQIMS suite will enable us to do structured problem-solving approaches like 8D, 7D, etc. In 8D, where you have the problem failure mode and the causes, and the different types of causes, actions coming out of this would go into the FMEA.

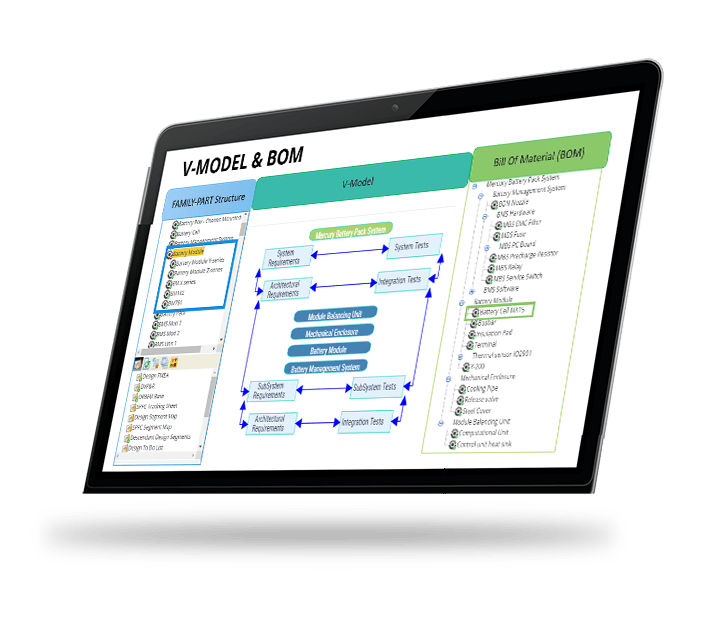

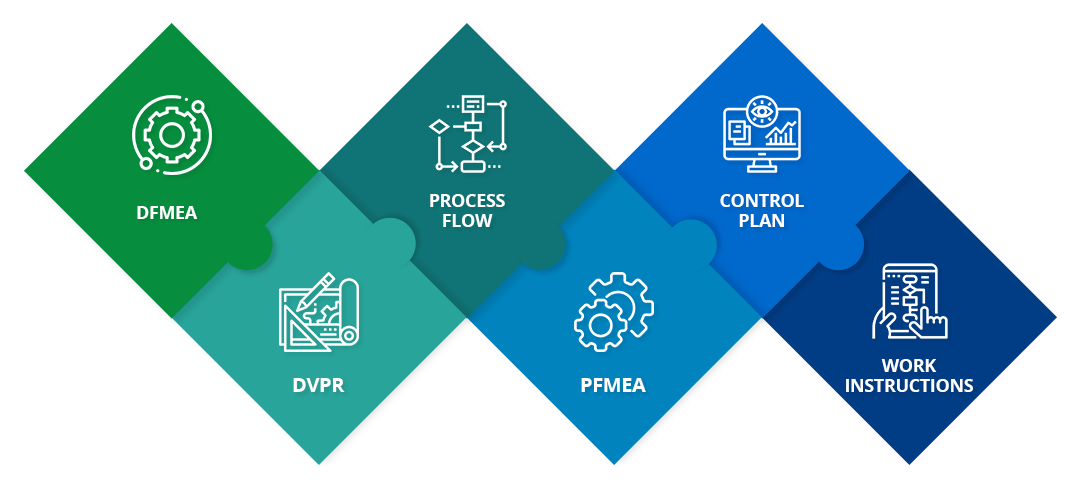

The part and foundation FMEAs shall be living documents that are always aligned. An update to the foundation FMEA Shall result in a review of the applicable information for Part FMEA. This process also shall work backward from the part FMEAs to the foundation FMEA. In addition, FMEAs shall be aligned with the control plans and work instructions/visual aids.

FMEA Software Suppliers shall use FMEA software which ensures the alignment of the Foundation FMEA, Part FMEA, control plan, and other applicable documents. AQuA Pro would help you ensure consistent linkages between the related documents. Within AQuA Pro, you could have your FMEA, DVP&R, and the special characters could also be then moved to Process flow Diagram, PFMEA, Control plan, Process work, Instructions, and so on.

AQuA Pro includes other tools like Boundary/Architecture Diagram, P-Diagram, Interface Function Matrix, Interface Matrix, DRBFM, and more.

SEGMENTS – Process and Design

Process segments help to capture best-in-class Process design company-wide. It cuts across process families standardizing processes. Analogous to Process Segments are Design Segments, a Design Segment Includes the Analysis of a product’s functions and requirements including all the related support documentation. A product can be created by including all the related design, segments, specific/unique functional requirements, and testing/ analysis.

Inheritance and Process Segments

Inheritance and Process Segments make it faster to create new parts and make it possible to update groups of parts simultaneously when a change affects the entire group and enable the very rapid creation of new parts There is tremendous ROI in the AQuA Pro software with design and process reuse using inheritance and segments.

AQuA Pro is a cloud-based solution. Within this software, there are different solutions. It is moving towards a more platform approach from a modular approach where you have the integrated management system, the EV AV platform, new product development and the performance management platform and supplier management solution where your suppliers can connect to our system and perform supplier PPAP submissions.

AQuA Pro is the first software to provide Multi-point Failure and Artificial Intelligence.

REQUEST FOR DEMO

AIAG VDA introduced in 2019 has a 7-step approach starting from planning and preparation to structure analysis, function analysis, failure analysis, risk analysis, optimization and then results documentation.

This FMEA standard describes potential failure mode and effects analysis in design (DFMEA), supplemental FMEA-MSR, and potential failure mode and effects analysis in manufacturing and assembly processes (PFMEA). J1739 is based on the common FMEA format (AIAG FMEA 4th Edition Reference Manual), it has replaced RPN (Risk Priority Number) with AP (Action Priority), has updated ranking tables. It includes MSR (Monitoring and System Response) and also a defined 6-step process.

There are single-point faults and multi-point faults capabilities, FMEAs that have mechanical information would be single-point faults, whereas, in electronic systems, a lot of the faults would be multi-point faults. The FMEA solution has FTA as well as FMEDA. AQuA Pro is format agnostic, using AIAG, AIAG-VDA, and SAE J1739. the software satisfies Honda and BMW FMEA requirements, and its ROI is typically a few months.